What doesn’t kill you makes you stronger but this saying goes completely wrong with workplace accidents. They may not kill you but could leave you with lifelong disability. Adding on few essential safety tools could enhance your cost a bit but will definitely protect you in your workshop. Safety isn’t expensive, it is simply priceless.

Essential Safety Tips for Your Workshop:

- Spare time to read the machine manual you are working with, especially if it’s new. Before operating any machine, you must know your machine well. Always operate electric tools within their design limitations.

- Make sure your work space is ventilated so that fresh air is exchanged properly.

- Loose coats, flowy dresses and jewelries should be avoided.

- Long Hair should be tied and covered properly including the fringes especially when working with machine tools or other equipment with rotating spindles.

- Store electric equipments in a dry place when not in use.

- Keep work areas well lighted when operating electric tools.

- Ensure that cords from electric tools do not present a tripping hazard.

Essential Safety Tools for Your Workshop:

1. Eye Protection Shield: Eyes are the most important and delicate organs that needs protection in any workplace. Woodworkers’ machines produce lots of sawdust, bark, wood chips, wood scrap etc. It may straight away hit your eyes and may damage them. Wearing safety goggles keeps your eyes safe. You may also cover up your entire face with the help of face shield. The spectacles that we normally wear are not safety glasses as they are not impact resistant and may shatter.

2. Ear Protection: Low level of noise does not affect your hearing capability but if you are exposed to loud noise of woodworking machines for long hours, this might damage your hearing permanently. So, use ear plugs, ear muffs or other approved hearing protection while working in loud sound environment.

3. Mask Protection for Lungs: The sawdust produced by woodworking machine might enter your nose, mouth, food pipe or lungs if you are not covering up your mouth and nose with a basic dust mask. Chemicals like spirit, varnish and paints may also affect your sinus and lungs. So, opt for a good quality advanced mask if you are finishing your wooden products and make sure your workshop is well ventilated.

4. Hand Protection: Wearing safety gloves protect your hands from being injured while working on machines. Even a small splinter may injure your hand and cause pain. Opting for good quality gloves that protect from cutting through glove material is always better. For finishing up or gluing purpose, disposable gloves are best.

5. Foot Protection: It is always better to wear enclosed shoes or safety boots in workshop. Your feet will thank you if anything heavy lands on them and they remain safe in those safety boots.

6. Guards: The exposed moving parts of your bandsaw or any other machine should always be protected with guards. The belt, gears, shafts, pulleys, sprockets, spindles, drums, flywheels, chains, or other reciprocating, rotating, or moving parts of equipment must be safeguarded properly. Safety guards must never be removed when the machine is operating.

7. PPE KIT: A personal protective equipment (PPE) kit must be used as and when required. It always protect you in workshop if there is someone else working along with you in these tough time of corona widespread disease.

8. Table Saw Push Stick for Bandsaw, Table saw & Bench Circular Saw: These are efficient low cost safety sticks for your bandsaw, table saw, bench circular saw or any other machine. These Push Sticks are strong, without being brittle, have an ergonomic handle with thumb rest (for a comfortable non-slip grip), a notched end and are long enough to keep your hands away from the blade. The Push Stick will not shatter or damage the blade if it accidently hits during use; after using one of these you won’t go back to using a piece of wood!

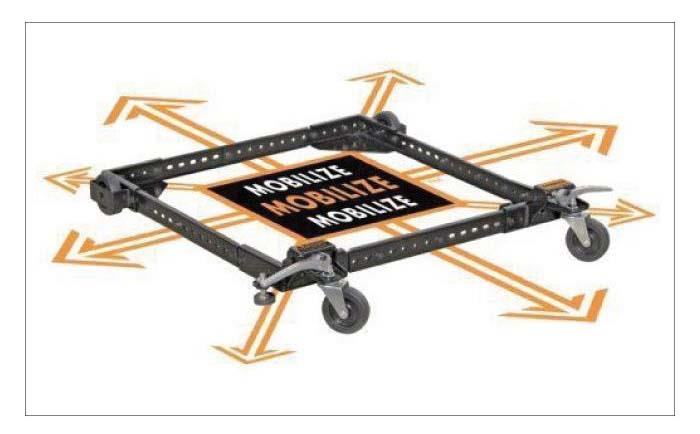

9.Universal Steel Mobile Wheel Base (Adjustable Frame : 250 kg Capacity): You’ll be able to open up space for more effective productivity, organize your workplace smoothly and safely. This all steel base is sturdy and easy to assemble, plus it adjusts to fit virtually any large woodworking machine, forming squares from 14 by 14 inches to 31 by 31 inches and rectangles as big as 19 by 43 inches. The foot-operated levers lock machines to the floor, and the base also features a durable powder-coated finish.

10. Double Insulated Tools: Double-insulated tools are available that provide protection against electrical shock without the third-wire grounding. In double-insulated tools, an internal layer of protective insulation completely isolates the external housing of the tool. Electrical shocks may result in serious injuries such as burns, heart fibrillation or even heart failure. To protect you from getting shock and burns, electric tools must have a three-wire cord with a ground and be plugged into a grounded receptacle. They should be double insulated or be powered by a low-voltage isolation transformer for safety reasons.